Performing tests, samples and checks before undertaking any work related to the coating of metal and plastic is fundamental in order to understand the potential outcome, so as to be able to propose the best possible solution and always know precisely what to expect from a specific type of treatment.

It should always be remembered that the coating is not always just an aesthetic parameter – it is often also an important factor in combating corrosion, oxidation and the action of other external agents that could limit the lifecycle of an item, such as water and the sun.

In the case in question, it is important to understand whether the coating is adhering perfectly to the surface or whether problems might arise, even if, at first glance, everything seems to be running smoothly.

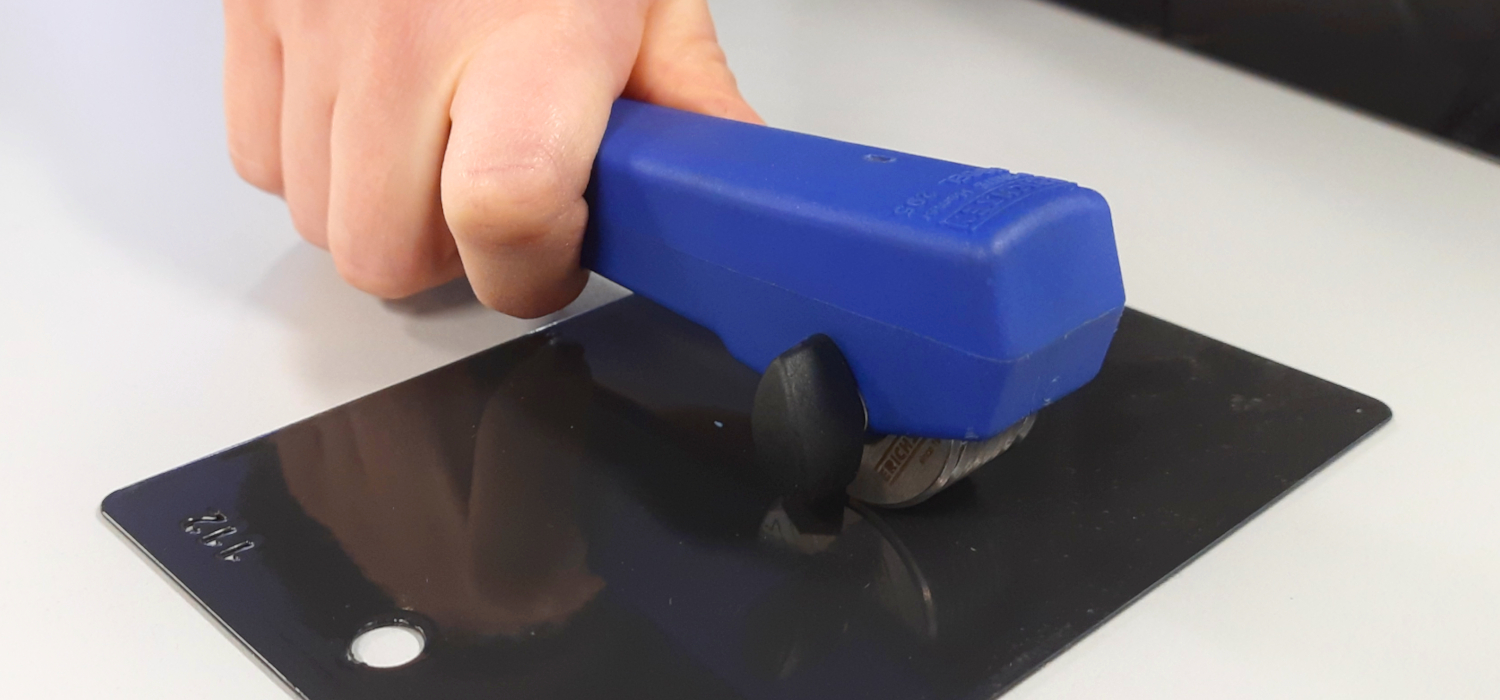

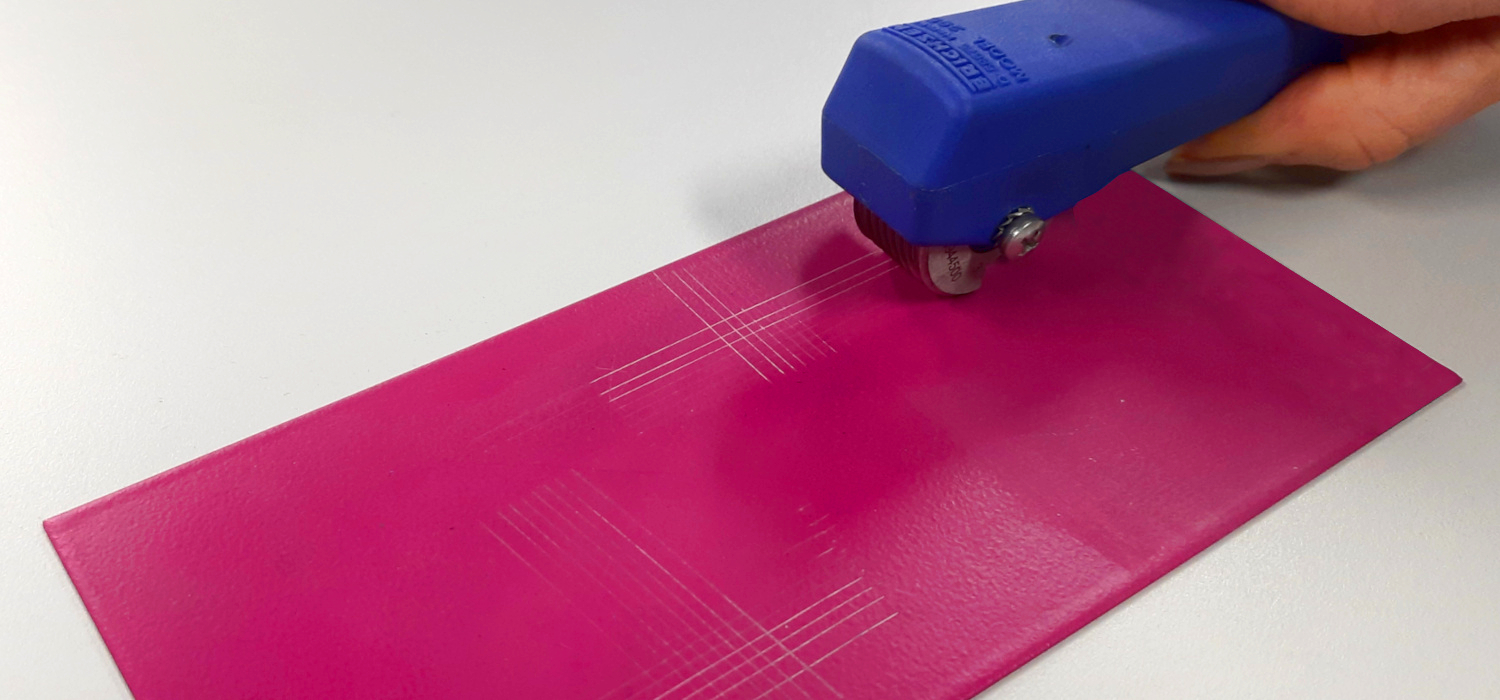

A very effective test to check the compactness and adherence of the existing coating consists of making a number of incisions on the surface concerned, spaced a couple of millimeters apart. These incisions should be deep enough to directly touch the surface underneath the layer of paint.

With the help of a crosshatch tester, also called adhesion tester, it is necessary to form a grid through a series of horizontal and vertical incisions, forming squares of the dimensions of 1x1mm, 2x2mm or 3x3mm.

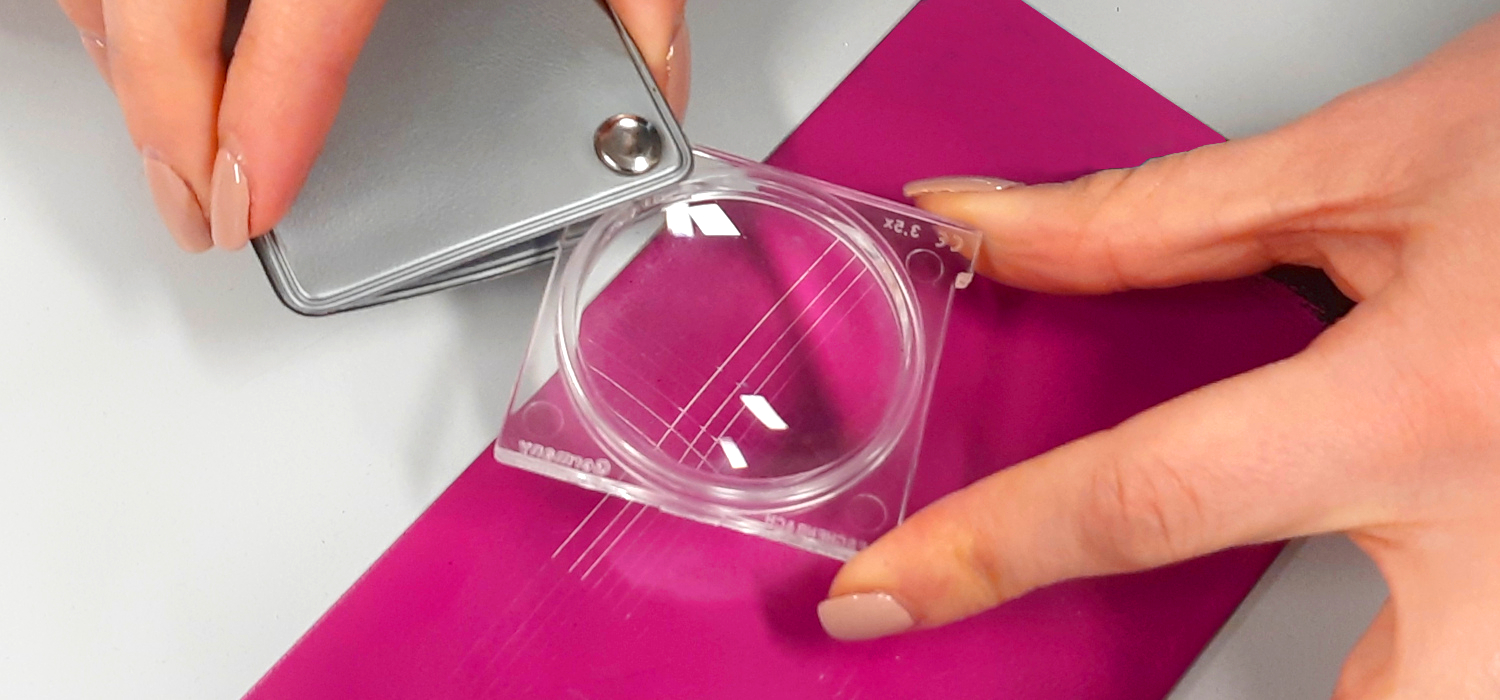

After making the incisions, it will be sufficient to place on the interested part a Permacel or 3M adhesive tape (specifically designed for the cross-hatching tests).

If, when the tape is removed, part of the paint remains attached to the adhesive, it means that adhesion is poor and, therefore, applying a further coat of paint over it could certainly lead to its detachment.

This check, known as adhesion test, is a quick and simple way of assessing the adhesion of coating systems; it is very useful in order to avoid starting to paint a surface that has poor adhesion, and will avoid having to redo a job because it was not carefully assessed at the outset.

If the grid that has been created is completely flat, with the edges of the lines perfectly clear, this means that the coating is suitable and it will be possible, if required, to apply a further layer of coating on top of the current one (this is the case with the ISO 0 value).

If, on the other hand, the edges of the lines are not clear-cut, but there are detachments of coating at the corners or along the various lines, it means that the treatment is not perfectly adherent to the surface. In this case, it will be necessary to assess the level of seriousness of the situation, with an ISO value that can range from 1 to 5, where 1 represents small detachments from the intersections of the lines (equal to no more than 5% of the area tested) and 5 represents a level of detachment that exceeds 65% of the area, a situation that is absolutely not compatible with a need for coating and that will require a total scraping of the current surface before it can be processed further.

The reference standard that regulates this test is ISO 2409:2020, where the test method is clearly defined, with indications detailing how to carry out the test in a suitable manner.

Our in-house laboratory is fully capable of performing the test, with experienced technicians who can carry it out in a short time and safely reveal the result.

The squaring test is one of the simplest and most practical methods to understand if the adhesion of a coating is optimal or not, both on metal and plastic support, and for this reason its use is strongly recommended.

Would you like to receive more information? Contact us by writing to info@zoccaratoverniciature.it or by calling the number +39 049 9202150.

English

English Italiano

Italiano